Process treatment manual for "water washing tower+alkali washing tower+activated carbon adsorption tower"!

In modern industrial production, exhaust gas treatment is a crucial step. The "water washing tower+alkali washing tower+activated carbon adsorption tower" process, as a comprehensive waste gas treatment solution, has gradually been accepted and applied by various industries due to its excellent treatment effect and wide applicability. Numerical activated carbon will provide a detailed introduction to the working principle, application scope, advantages and disadvantages, as well as precautions in practical applications of this process, to help readers gain a deeper understanding of this waste gas treatment technology.

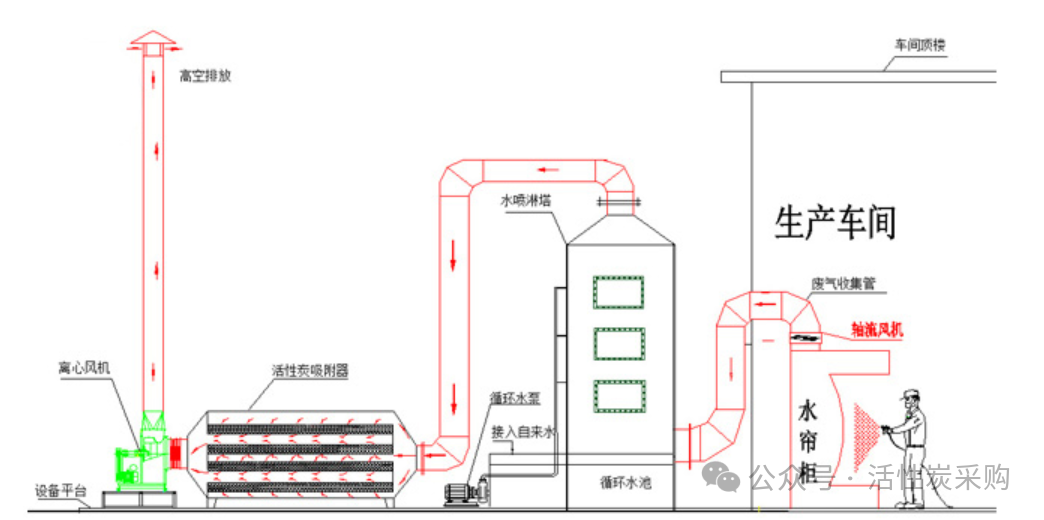

1、 The working principle and application of water washing tower.

1.1 Working principle.

Water washing tower, also known as spray tower or washing tower, mainly absorbs pollutants from gas into liquid through the contact between water and gas, thereby achieving the purpose of purifying gas. Its working principle can be summarized as the following steps:

1. Gas liquid contact: The exhaust gas enters through the bottom of the tower and comes into full contact with the water sprayed from the top of the tower.

2. Pollutant absorption: Pollutants in exhaust gas dissolve or are adsorbed into water during contact with water.

3. Purified gas discharge: The purified gas after washing is discharged from the top of the tower.

1.2 Scope of application.

Water washing towers are widely used in the pretreatment of various industrial waste gases, especially suitable for the following situations:

Soluble gases: such as hydrogen chloride, ammonia, hydrogen sulfide, etc.

Particulate matter: It has a good removal effect on particulate pollutants such as dust and smoke.

1.3 Classification of washing towers.

Water washing towers can be divided into the following categories based on their structure and function:

Packing tower: By increasing the gas-liquid contact area through the packing layer, the absorption efficiency is improved.

Spray tower: Use nozzles to evenly spray the washing liquid, forming a liquid film that comes into contact with the gas.

Plate tower: Increasing gas-liquid contact opportunities through multiple plate layers inside the tower.

Bubble Tower: Utilizing gas bubbling to enhance gas-liquid contact.

Venturi scrubber: Utilizing the efficient mixing effect of Venturi tubes to achieve efficient purification of exhaust gases.

Acid alkali waste gas scrubbing tower: specifically designed to remove acidic and alkaline gases.

Wet dust collector: mainly used for dust removal.

2、 The working principle and application of alkali washing tower.

2.1 Working principle

The alkaline washing tower is based on the water washing tower, and enhances the absorption effect of acidic gases by adding alkaline solutions (such as sodium hydroxide, potassium hydroxide, etc.) to the washing solution. Its working principle is similar to that of a water washing tower, mainly including the following steps:

Gas liquid contact: The exhaust gas enters through the bottom of the tower and comes into full contact with the alkaline washing solution sprayed from the top of the tower.

Chemical reaction: Acidic pollutants in exhaust gas (such as sulfur dioxide, hydrogen chloride, etc.) undergo neutralization reaction with alkaline detergent, generating salts and water, which are then absorbed.

Purified gas discharge: The purified gas after alkali washing is discharged from the top of the tower.

2.2 Scope of Application

Alkali washing towers are widely used to treat waste gases containing acidic gases, especially suitable for the following situations:

Acidic gases: such as sulfur dioxide, hydrogen chloride, hydrogen fluoride, etc.

Organic acid vapor: such as acetic acid vapor, etc.

2.3 Alkali washing tower supporting equipment

Alkali washing towers are usually equipped with the following equipment:

Water pump: such as trough water pump, vertical water pump, etc., used for circulating alkali solution.

Fan: Centrifugal universal fans such as explosion-proof, non explosion-proof, anti-corrosion, high-temperature, etc., used for conveying exhaust gas.

2.4 Advantages and disadvantages

advantage:

Has high removal efficiency for acidic gases.

Suitable for the treatment of various acidic waste gases.

Disadvantages:

Alkaline agents need to be consumed during operation, resulting in high operating costs.

It is necessary to dispose of the treated waste liquid properly to avoid secondary pollution.

3、 Working principle and application of activated carbon adsorption tower

3.1 Working principle

The activated carbon adsorption tower utilizes the strong adsorption capacity of square activated carbon to adsorb organic pollutants and some inorganic pollutants in exhaust gas onto the surface of activated carbon through two mechanisms: physical adsorption and chemical adsorption, thereby achieving purification. Its working principle mainly includes the following steps:

Gas entry: The exhaust gas enters through the bottom of the tower and comes into contact with the activated carbon filled inside the tower.

Pollutant adsorption: Pollutants in exhaust gas are adsorbed into the pore structure of activated carbon when passing through the activated carbon layer.

Purified gas discharge: The purified gas after adsorption treatment is discharged from the top of the tower.

3.2 Scope of Application

Activated carbon adsorption towers are widely used in the treatment of various organic waste gases, especially suitable for the following situations:

Volatile Organic Compounds (VOCs): such as benzene, toluene, xylene, etc.

Odorous gases: such as hydrogen sulfide, ammonia, etc.

Low concentration, high air volume: Especially suitable for the treatment of organic waste gas with low concentration and high air volume.

3.3 Advantages and disadvantages

advantage:

High adsorption efficiency for organic pollutants.

The device has a compact structure and occupies a small area.

Easy to operate and stable to run.

Disadvantages:

Activated carbon requires regular replacement or regeneration, resulting in high operating costs.

The treatment effect of high concentration exhaust gas is poor and needs to be combined with other processes.

4、 Operating instructions for activated carbon adsorption tower

4.1 System activation

Open the air door corresponding to the inlet of the fan that needs to be operated.

Turn on the power.

Set the pressure difference and start the fan.

Confirm the exhaust status.

4.2 System shutdown

Confirm that the system can be shut down and all production systems are allowed to shut down.

Turn off the system fan.

Close the air door.

Turn off the power.

5、 Method for replacing activated carbon

Each activated carbon adsorption device is equipped with two carbon boxes, which are fixed to the outer shell of the adsorption device by hexagonal bolts. When replacing the activated carbon, the hexagonal bolts should be removed first.

Replacing activated carbon: Generally, it needs to be replaced after 3-6 months of use (depending on the concentration of exhaust gas). The commonly used square activated carbon includes honeycomb activated carbon and columnar activated carbon. The iodine value of honeycomb activated carbon shall not be less than 650mg/g, and the iodine value of columnar activated carbon shall not be less than 800mg/g. Take out the old activated carbon at once, avoiding excessive vibration and force to prevent it from breaking and falling into the equipment (difficult to clean). When installing new carbon, the same situation should be avoided, and it should be placed flat and tightly.

After replacing the paint mist activated carbon, the cover is restored and fixed with hexagonal bolts. The replacement is complete.

6、 The advantages of the combination process of "water washing tower+alkali washing tower+activated carbon adsorption tower"

6.1 Strong comprehensive processing ability

The combination process of "water washing tower+alkali washing tower+activated carbon adsorption tower" effectively solves the limitations of a single treatment process in dealing with complex waste gas components through multi-stage treatment. The water washing tower mainly removes soluble gases and particulate matter, the alkali washing tower effectively treats acidic gases, and the activated carbon adsorption tower targets organic waste gas and residual pollutants. The combination of the three ensures efficient purification of waste gas.

6.2 Wide adaptability

This combination process is suitable for various types of industrial waste gases, especially performing well in treating waste gases with complex components and diverse types of pollutants. Whether in the chemical, pharmaceutical, printing, or spray coating industries, this process can achieve efficient waste gas treatment.

6.3 Stable operation and easy operation

Through scientific process design and automation control system, the combination process of "water washing tower+alkali washing tower+activated carbon adsorption tower" has high stability during operation. The coordinated work between each processing unit ensures the efficient operation of the overall system, and is easy to operate and maintain, reducing faults and downtime during operation.

7、 Precautions in practical applications

7.1 The Importance of Preprocessing

In practical applications, in order to ensure the treatment effect of the combination process of "water washing tower+alkali washing tower+activated carbon adsorption tower", the pretreatment of exhaust gas is very important. By appropriate pretreatment methods such as cooling and dust removal, the temperature and dust content of exhaust gas can be reduced, the load on subsequent treatment units can be reduced, and the overall treatment efficiency can be improved.

7.2 Equipment selection and design

Reasonably selecting and designing the specifications and parameters of each treatment unit based on the composition, concentration, and treatment requirements of the exhaust gas is the key to ensuring the operational effectiveness and economy of the system. Especially when dealing with high concentration exhaust gas, it is necessary to fully consider the processing capacity and saturation time of each processing unit, in order to avoid poor treatment effect or high operating costs due to improper equipment selection.

7.3 Maintenance and Management

Regular maintenance and management are essential to ensure the long-term stable operation of the system. Cleaning the fillers in the washing tower and alkali washing tower, replacing activated carbon, inspecting and maintaining equipment such as pumps and fans, and monitoring and adjusting the operating parameters of the system are all important measures to ensure efficient operation of the system.

8、 The importance of combination technology

The combination process of "water washing tower+alkali washing tower+activated carbon adsorption tower" is an efficient and comprehensive waste gas treatment solution that effectively solves the problem of complex waste gas components through multi-stage treatment. Its wide applicability and stable operating performance have made it widely used in exhaust gas treatment in various industries. However, in practical applications, reasonable pretreatment, scientific equipment selection and design, and regular maintenance management are all key to ensuring the efficient operation of the process. Through continuous optimization and improvement, we believe that this process will play a more important role in the future environmental protection industry.